The utilization

circulation

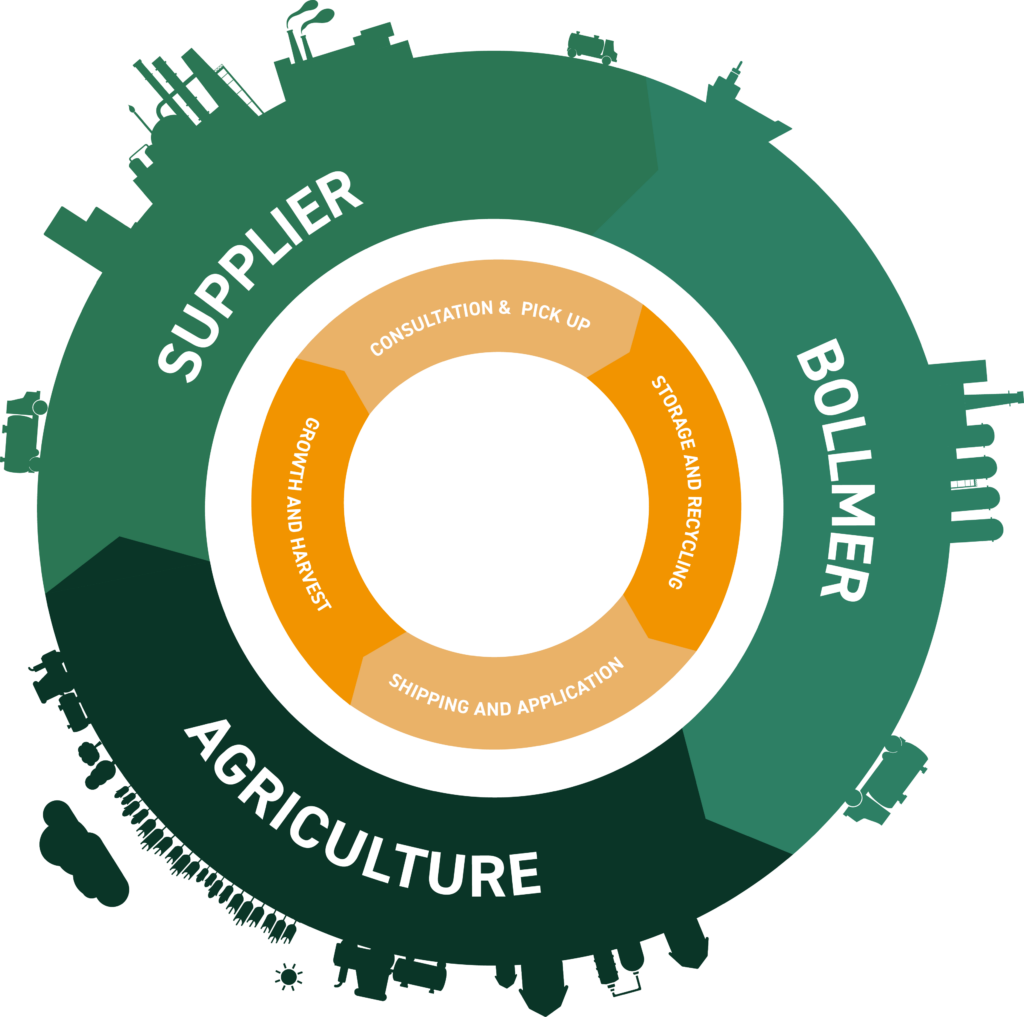

In various production processes, substances with partly unknown potential are produced. In keeping with the circular economy, Bollmer offers a wide range of options for industrial process chains to make the nutrients contained in by-products, such as nitrogen, potassium, phosphorus, sulfur or lime, usable again for plants.

We are a strong link between industry and agriculture. We support our suppliers from various sectors with individual, sustainable concepts for the nutrient recycling of organic and mineral by-products. In our in-house laboratories and processing facilities, these substances are turned into high-quality, needs-based fertilizers with plant-available nutrients for efficient, sustainable agriculture. With our circular economy, we create multi-win situations.

With our fertilizers and recycled fertilizers made from organic and mineral base materials, we offer both conventional and organic farms a wide range of plant nutrition options. Our fertilizers and customized services, from storage and delivery to professional application, conserve resources and are suitable for any form of agriculture.

Recovery-

concepts

For all companies that have defined material flows with contents of nitrogen, phosphorus, potassium or other nutrients, we are happy to examine all possibilities within the framework of a suitability test. Our recycling concepts always address the diverse site conditions of the customers and show the individual potentials. In just a few steps, our customers can find out what sustainable recycling solutions are available for their material from a legal and technical perspective. Improve your environmental footprint with us and reduce your CO₂ footprint.

01

Request

True to the motto “It doesn’t cost anything to ask”, we look forward to receiving your inquiry with an initial brief description of your starting material, your processes and your ideas.

02

Suitability test

After a detailed initial discussion, we subject the samples from your manufacturing process to a substance test. Among other things, we evaluate the quality of the nutrients present/fixed.

03

Recycling concept

In the last step, possible applications are checked for feasibility and the respective costs and revenues are compared. Together we go into the decision-making process.

A partner you

can rely on.

A partner you can rely on.

Just-in-Time

We provide our industrial customers with collection guarantees to ensure a continuous production flow. To ensure that the recyclable by-products and waste are collected on time, we have built up storage and handling capacities at various locations as well as reliable truck and ship logistics

Storage capacity

Nationwide, Bollmer has a storage capacity of more than 200,000 tons, including tank facilities for the storage of approximately 120,000 tons of liquid materials. In this way, we achieve a reliable uptake of all raw materials and the availability of our fertilizers as needed at any time.

Utilization concepts

We analyze the material composition and nutrient content of the by-products and residues generated in industrial processes and evaluate the potential for recycling into organic and mineral recycled fertilizer.